The useful knowledge about watches (3)

The useful knowledge about watches (3)

Today, I will continue to bring you four useful knowledge about watches, let's go.

Why are guilloche watches so expensive?

The word "Guilloche" is derived from the French guillochis. Its original meaning is a machine-created precise and regular engraving process containing straight and circular patterns.

Making a guilloche dial is very complicated, and the engraver's hands must operate the engraving tools on the engraving lathe; one hand is assisted by the lathe to rotate the gold plate, while the other hand applies pressure to the engraving tool to control the tip, which is on the surface. The plate is engraved with a finely designed machine-cut pattern.

As the cam rotates, moving the milling head in different directions, while the dial moves back and forth on the lathe, the beautifully engraved pattern is born. No small mistakes are allowed in this whole process, even a small step is enough to destroy the entire dial. Therefore, the guilloche watch is more flexible and luxurious.

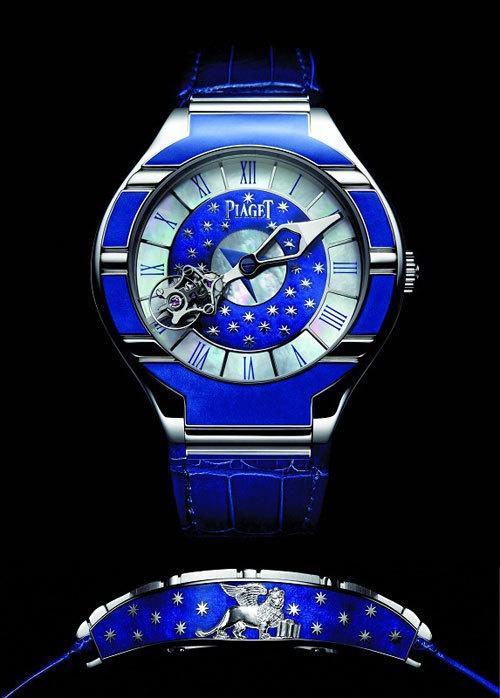

What is an enamel watch?

Enamel watches represent a timeless topic and love of watch collectors, as well as unimaginably expensive prices. Enamel watches are divided into three types: cloisonné enamel, micro-painted enamel and chisel enamel. Take the most common cloisonné enamel as an example, it is necessary to bend a gold wire less than 0.5MM into a pattern and fix it on the surface of the enamel base glaze. After the first firing, the pattern outlined by the wire is filled with the enamel glaze as designed.

After the enamel coating is dried, it must be calcined in a kiln at a high temperature of over 800°C, so that the enamel will fuse with the metal base and become very strong and stable. Once a glaze cracks in the process, the entire dial will be scrapped. The success rate of making cloisonné enamel dials is less than 50%, so it is very precious. All enamel watches that appear at auctions are sold for sky-high prices.

What is a gooseneck spinner?

In the introduction of Glashütte watches, we often see "gooseneck fine-tuning". What is the role of gooseneck fine-tuning?

The gooseneck fine-tuning exists to adjust the speed needle, avoiding the unavoidable large deviation of the speed needle. The main principle is to use the elasticity of the metal sheet to clamp the speed needle, and then finely adjust the speed needle deviation through a small screw. After the adjustment is done, the speed needle is firmly fixed. Because the shape of the device resembles the graceful curve of the neck of a swan, this fine-tuning device is called gooseneck fine-tuning.

Grinding pattern other than Geneva pattern

The competition of high-end watches is common in the movement used. In order to show the exquisite craftsmanship, watchmakers often perform superb manual polishing on the movement, making the original ordinary movement rich in edges and corners and patterns, increasing the beauty.

The most commonly seen is the Geneva pattern, which is named after the surface of the sparkling Lake Geneva. The Geneva pattern is further divided into striped, annular and radial ripples. Among them, the strip corrugations often occupy a large area of the plywood and automatic oscillating weight of the movement, and are also dotted with red and sapphire.

In addition to the Geneva pattern, there are many more delicate sun patterns. The sun patterns have a radial shape and are often installed on the outermost ring of the splint or on various connecting shafts of the movement.

The pearl pattern is very similar to the fish scale pattern, but compared with the fish scale pattern, the overlapping area of the pearl pattern is smaller and the pattern is more uneven. Now it is only used in a small part to assist the creation of the movement layering.